Industry Centers

Mechanical Fittings

Medical Devices

Lighting Tools

New Energy

Precision Parts

Auto Industry

Aerospace

Handboard

Various Parts

Custom requirements for trial production in all walks of life

Various processing technologies and surface treatment technologies involving metal and plastic parts meet the different needs of trial production and parts manufacturing in all walks of life, including CNC parts processing, rapid injection molding, sheet metal, painting, oxidation, powder spraying, electroplating, etc.

From CNC hand board processing to small batch customization

From 1 piece to 10000 piece, we provide a variety of parts processing solutions to meet your exact specifications. When you need to deliver customized parts in a short time, we can provide engineering support without any restrictions.

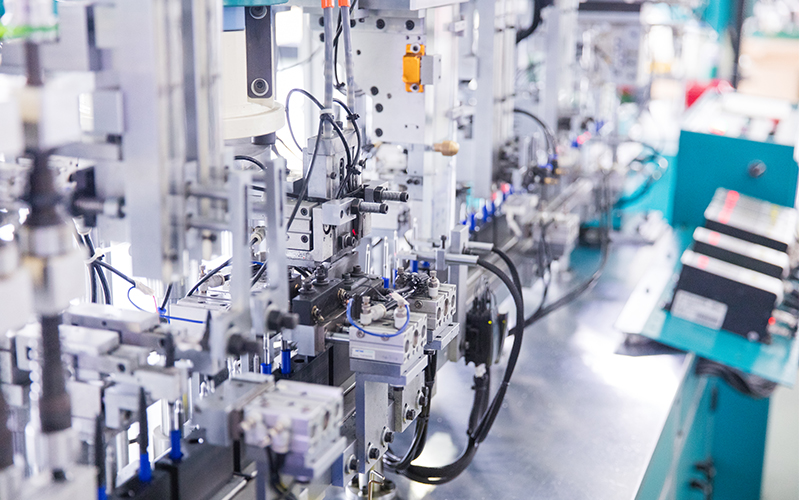

Flexible and efficient production process management

The implementation of lean production methods, professional project management and technical expertise engineering team, from design optimization suggestions to production process improvement to achieve high efficiency and high quality, and continue to improve customer satisfaction.

Find the Advantages of Customizing CNC Machining for Parts for You

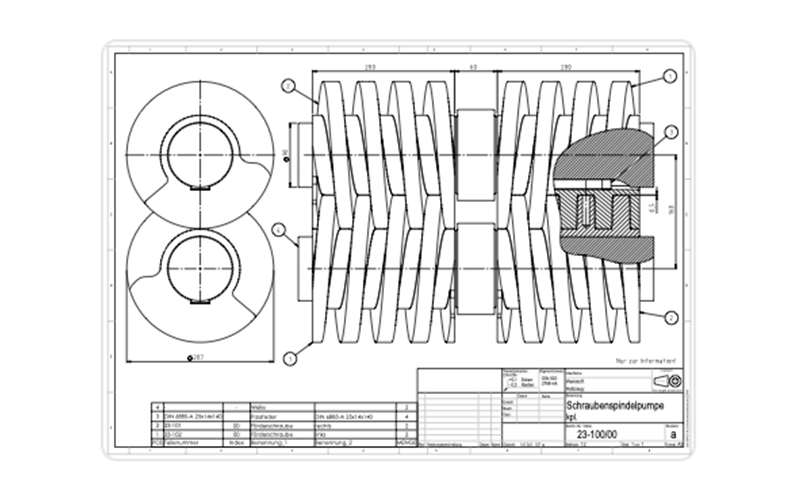

Optimized DFM recommendations

Design problems can be discovered in advance without waiting for production. Our engineers will provide cost-effective rationalization suggestions in terms of design, materials, craftsmanship and manufacturability.

One-stop post-processing

We not only provide a complete post-treatment process internally, including polishing, polishing, sandblasting, painting, printing, etc., but also provide various special surface treatment options such as oxidation, dusting, electroplating, etc. in combination with external resources.

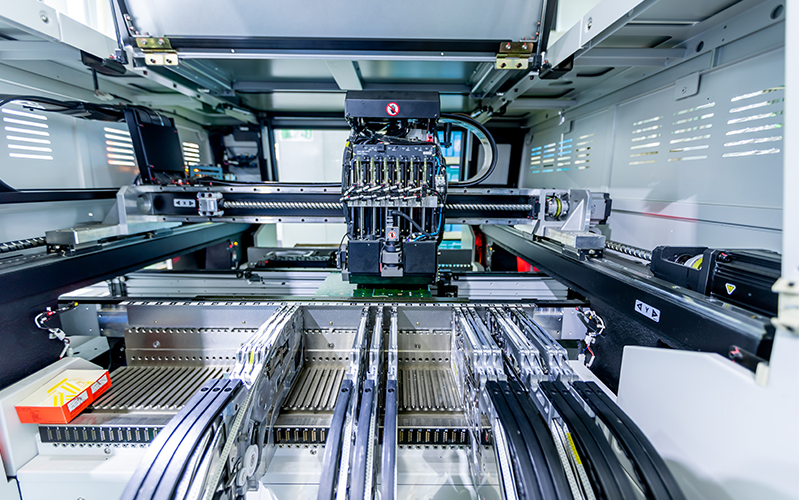

Advanced processing technology

We are equipped with advanced 3-axis, 4-axis and 5-axis CNC machining equipment, which can provide different types of precision CNC machining, including milling and turning, as well as auxiliary EDM and wire cutting machining.

ISO9001 certification factory

We are committed to continuous improvement and optimization of the quality control process. The professionally trained quality inspection team has advanced testing instruments such as three-coordinate measuring instruments and 3D scanners to ensure that your project meets strict quality specifications.

CNC parts processing meets your strictest specifications

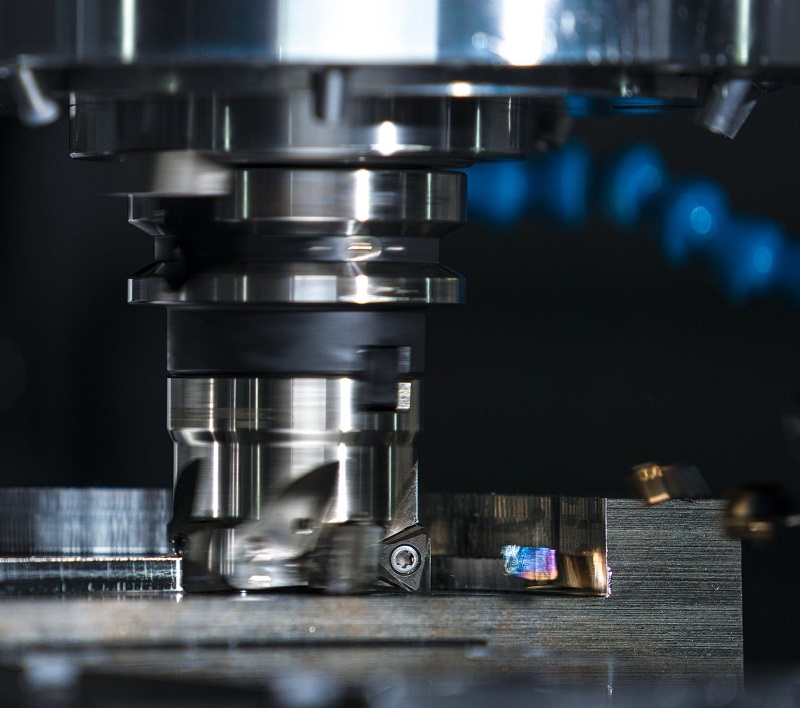

CNC Machining of Metal Parts

Composite Processing Capacity of Supporting Resources

Provide a wide range of CNC machining of metal materials, including aluminum alloy, magnesium alloy, zinc alloy, titanium alloy, stainless steel, etc., supporting the ability of turning and milling composite machining, providing the highest possible precision and efficiency for the precision machining of parts.

CNC Machining of Plastic Parts

Customized Handboard Processing Solution

CNC machining of more than 30 engineering grade plastics, from visual design models to functional hand boards, we focus on machining plastic parts with complex curved surfaces and structures, customizing finishing, high tolerance, optical transparency, and various surface treatment processes for you.

Our team of experienced manufacturing experts, mechanics and engineers provide high-quality CNC parts within your deadline. Whether you are looking for disposable hand boards or small batch production, we will cooperate with you to make your design a reality.